|

Mount with WebDAV

RSS Feed for this Album

View Latest Updates

View Popular Items

View Random Items

View Slideshow (Fullscreen)

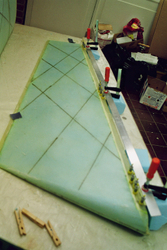

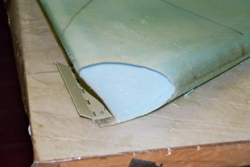

Jeroen Glazener Kit 615 PH-GLZ1. In the... 2. Picking up ... 3. Chapter 1 ... 4. Chapter 2 ... 5. Chapter 3... 6. Chapter 4... 7. Chapter 6... ... 41. Upholstery |

Page:

1

2

|