|

Mount with WebDAV

RSS Feed for this Album

View Latest Updates

View Popular Items

View Random Items

View Slideshow (Fullscreen)

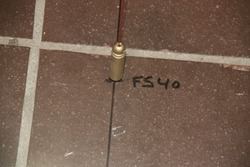

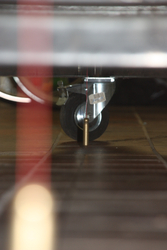

Jeroen Glazener Kit 615 PH-GLZ1. In the... ... 20. Chapter 20 ... 21. Chapter 21T... 22. Chapter 22 ... 23. Chapter 29 ... 24. Chapter 23 ... 25. The dream... 26. Chapter 25 ... ... 41. Upholstery |

|