|

Mount with WebDAV

RSS Feed for this Album

View Latest Updates

View Popular Items

View Random Items

View Slideshow (Fullscreen)

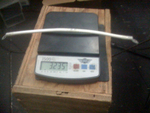

Jeroen Glazener Kit 615 PH-GLZ1. In the... ... 15. Mod 65... 16. October... 17. Chapter 17 ... 18. Chapter 18 ... 19. Chapter 19 ... 20. Chapter 20 ... 21. Chapter 21T... ... 41. Upholstery |

Page:

1

|